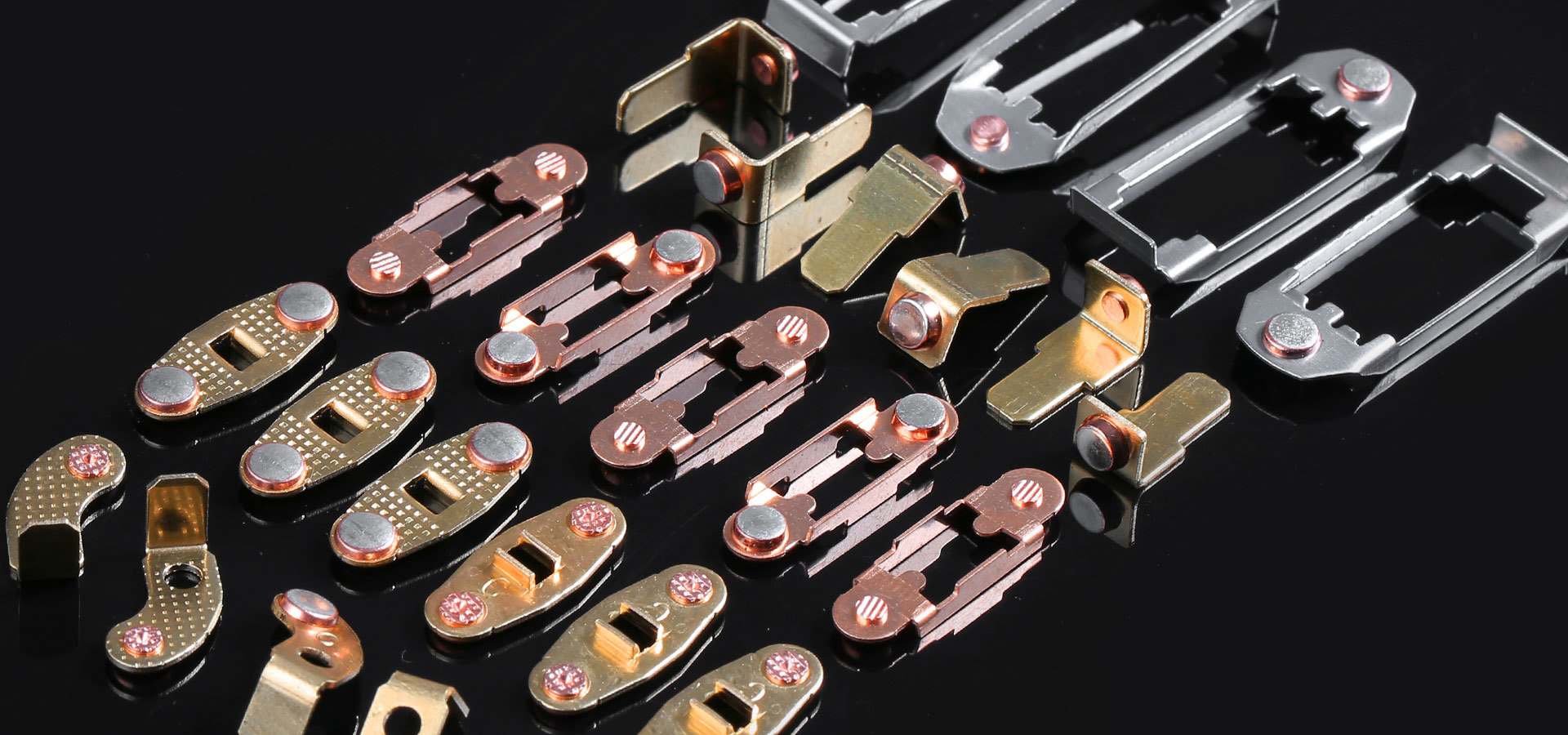

Types of rivets and their uses

Release Time:

Dec 26,2023

Commonly used are R-type rivets, fan rivets, blind rivets (strike core rivets), tree rivets, semi-circular head, flat head, semi-hollow rivets, solid rivets, countersunk head rivets, blind rivets, hollow rivets, which are usually connected to the riveted parts by the use of their own deformation. Cold rivets are generally used for sizes less than 8mm and hot rivets for sizes greater than this. But there are exceptions, such as certain locks on the nameplate, is the use of rivets and lock body hole of the surplus riveted.

Commonly used are R-type rivets, fan rivets, blind rivets (strike core rivets), tree rivets, semi-circular head, flat head, semi-hollow rivets, solid rivets, countersunk head rivets, blind rivets, hollow rivets, which are usually connected to the riveted parts by the use of their own deformation. Cold rivets are generally used for sizes less than 8mm and hot rivets for sizes greater than this. But there are exceptions, such as certain locks on the nameplate, is the use of rivets and lock body hole of the surplus riveted.

R-type plastic rivets, also known as expansion rivets, by the plastic sub-nail and female buckle two parts. Its installation in the installation without the use of installation tools, the installation base placed in a smooth hole, and then press the head, the special design of the foot after the force of the expansion of the support, firmly locked in the installed surface. It is commonly used to connect plastic shells, lightweight plates, insulation materials, circuit boards, or any other thin, lightweight materials, beautiful and practical, easy to use.

Fan rivets are specially designed for manual installation and can be pulled through holes in the panelling or chassis, and are made from elastomeric materials with good toughness for fast installation even in overfilled assemblies. Cleverly designed with elastic function with the corresponding aperture after pulling in is not easy to slip out, fan rivets are mainly used in electronic computer chassis fans, heatsinks and chips fixed between the use of anti-vibration, reduce noise.

Strike core rivets are very convenient riveting new riveting fasteners, in a relatively small space or no rivet gun or can not use a rivet gun in the environment strike core rivets can show their unique advantages. The use of hammers and other objects to hit the core of the nail on one side can be two or more connected parts riveted together successfully. Striking core rivets in accordance with the shape of the nail cap brim can be divided into flat round head striking core rivets and countersunk head striking core rivets, according to the different combinations of materials can be divided into all-aluminium striking core rivets, aluminium-steel striking core rivets, all-stainless steel striking core rivets, steel steel striking core rivets, aluminium-stainless steel striking core rivets, plastic striking core rivets and so on. Striking core rivets do not have to use manual riveting gun or pneumatic riveting gun to riveting like core-pulling rivets, there is a better riveting and convenience, can be widely used in a variety of connected parts riveting.

Plastic tree rivets also known as inverted tooth plastic rivets also known as Christmas tree type plastic rivets, toothed piece of good elasticity can be installed in the round holes of the interference assembly directly by manual pressure, toothed piece can be adjusted according to the actual thickness of the size of their own to be fixed, the inverted tooth design is that the rivets are installed after the installation of the surface firmly fixed to the installation, not easy to be pulled out, suitable for foam, wood, rubber, automotive interiors and other soft materials for the use of fixing. It is suitable for fixing between soft materials such as foam, wood, rubber, car interiors, etc. Plastic tree rivets have excellent insulation, fire performance, non-magnetic, heat insulation, light weight, high temperature, high strength, corrosion resistance, widely used in various industrial fields.

Rivet types can be broadly divided into open type, closed type, double drum type, single drum type series, the following on the respective models for a brief description. Countersunk head Blind Rivets: For riveting the surface of the riveted parts require a smooth and beautiful riveting. Double drum type blind rivets: riveting, the nail core will be riveted to the end of the body of the rivet nail body into a double drum shape, the two to be riveted to the structural components of the clamping, and can reduce the pressure on the surface of the structural components. Uses: Mainly used in a variety of vehicles, ships, construction, machinery, electronics and other industries riveting a variety of thin structural components. Large cap edge blind rivets: the rivets and ordinary blind rivets compared to its aluminium cap diameter increased significantly, the rivets in the riveting and connectors, with a larger contact area, has a stronger support surface which can enhance the torque strength, can withstand higher radial tension. Applicable industries: suitable for fastening soft, fragile surface materials and oversized holes, increased cap diameter for soft materials have special protection applications. Sealed Blind Rivets: Designed to enclose the mandrel head after riveting, very suitable for a variety of applications with waterproofing requirements. High shear, anti-vibration and high pressure resistant.

All-aluminium blind rivets the rivet body also uses high-quality aluminium wire, riveted beautiful and durable will never appear rust phenomenon: compared with ordinary blind rivets, rivets riveting strength is lower, suitable for materials softer connectors. Open end stainless steel rivets: the rivets are high tensile demand, corrosion-resistant choice. Semi-circular head rivets are mainly used for riveting occasions subject to large lateral loads, the most widely used. Flat cone head rivets due to fat nail head, can resist corrosion, commonly used in ship hulls, boiler tanks and other corrosive strong riveting occasions.

Countersunk head, semi-countersunk head, 1200 countersunk head, semi-countersunk head rivets are mainly used for the surface needs to be smooth, by the load is not big riveting occasions. Flat head rivets are used for general load riveting occasions. Flat head, flat round head rivets are mainly used for sheet metal or leather, canvas, wood and other non-metallic materials riveting occasions. Large flat head rivets are mainly used for non-metallic materials riveting occasions. Semi-hollow rivets are mainly used for riveting occasions with little load. Headless Rivets

Keywords:

More information