What is the difference between a semi-hollow rivet and a solid rivet?

Release Time:

Dec 26,2023

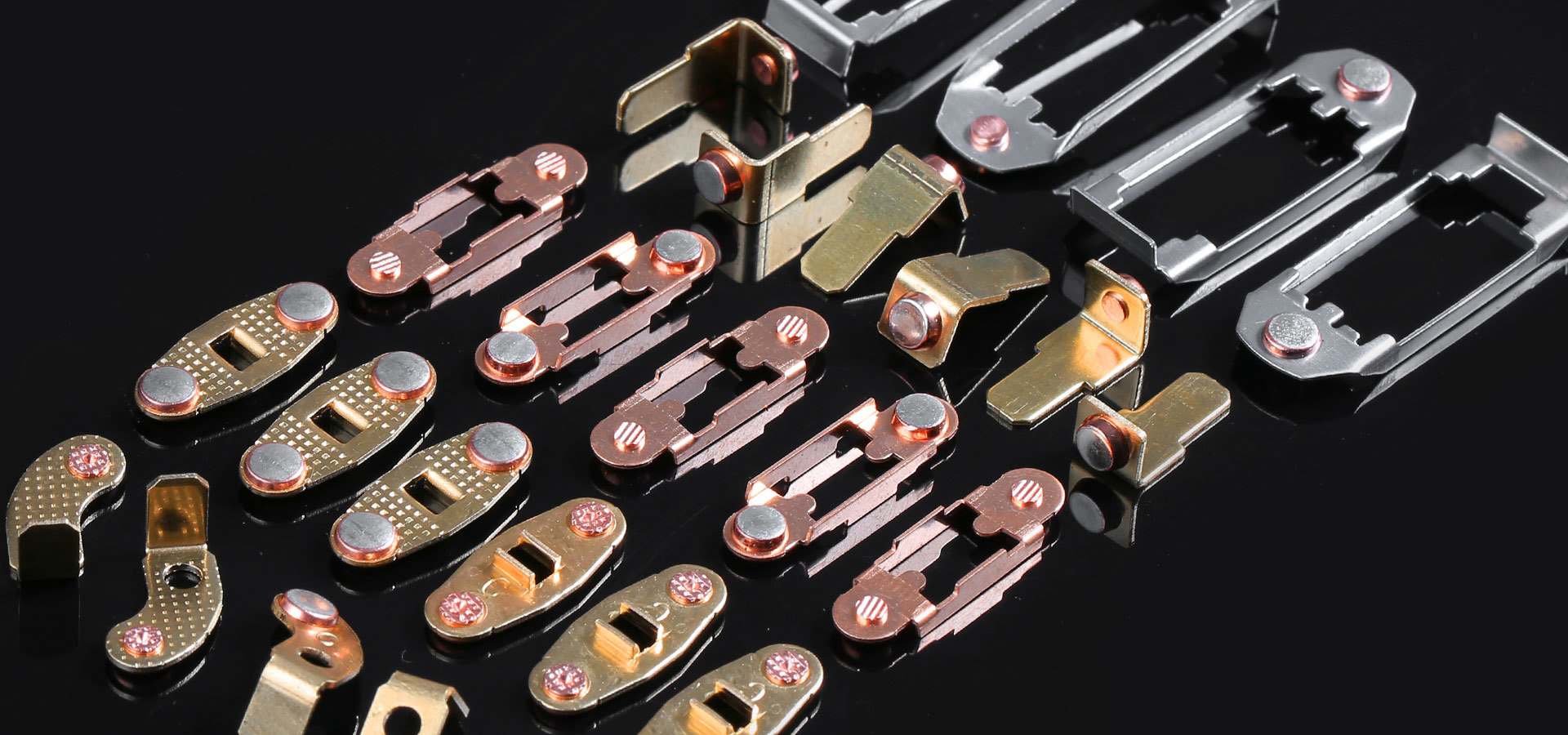

How about common solid rivets compared to semi-hollow rivets? When it comes to rivets, all of my friends should know that it is a type of metal fixing used to dry join various materials. It is not only varied but also very useful. The common ones are solid rivets and semi-hollow rivets. What is the self-punching of these two types of rivets? Let's see. The elastic deformation of a solid rivet is much drier than its plastic deformation, so only its elastic deformation is emphasised. The plates to be joined are fixed between the concave contact and the crimp ring, the rivets are fitted, the punch shaft moves down, the solid rivet penetrates the top and bottom plates, punching out small pieces of metal, and then some of the bottom plate is pressed into the ring groove by the reaction force of the lower die. This method will produce a bottom groove and interlocking joint.

How about common solid rivets compared to semi-hollow rivets? When it comes to rivets, all of my friends should know that it is a type of metal fixing used to dry join various materials. It is not only varied but also very useful. The common ones are solid rivets and semi-hollow rivets. What is the self-punching of these two types of rivets? Let's see. The elastic deformation of a solid rivet is much drier than its plastic deformation, so only its elastic deformation is emphasised. The plates to be joined are fixed between the concave contact and the crimp ring, the rivets are fitted, the punch shaft moves down, the solid rivet penetrates the top and bottom plates, punching out small pieces of metal, and then some of the bottom plate is pressed into the ring groove by the reaction force of the lower die. This method will produce a bottom groove and interlocking joint.

The riveted joint enters the extrusion stage when the rivet is completely broken. When the rivet head is pressed into the plate, the direction of flow of the metal is influenced by the geometry of the thousand, which is attached to the geometrical boundary of the rivet in contact with the plate. The effect of edge forces on the quality of riveted joints. During the riveting process, if the pressure edge force is too high, part of the material is extruded from outside the die and the stress is concentrated on the lower plate.

The position of the material in contact with the concave mould leads to the collapse of the music pressure, and the unit will be deleted, affecting the riveting effect.The effect of inter-following on the quality of the connection, the inter-following between the rivet and the mould is directly related to the quality of the riveting contact surface. A proper follow can greatly reduce the cutting work and obtain a better cross-section, thus achieving a better extrusion and filling effect in the moulding stage.

Keywords:

More information