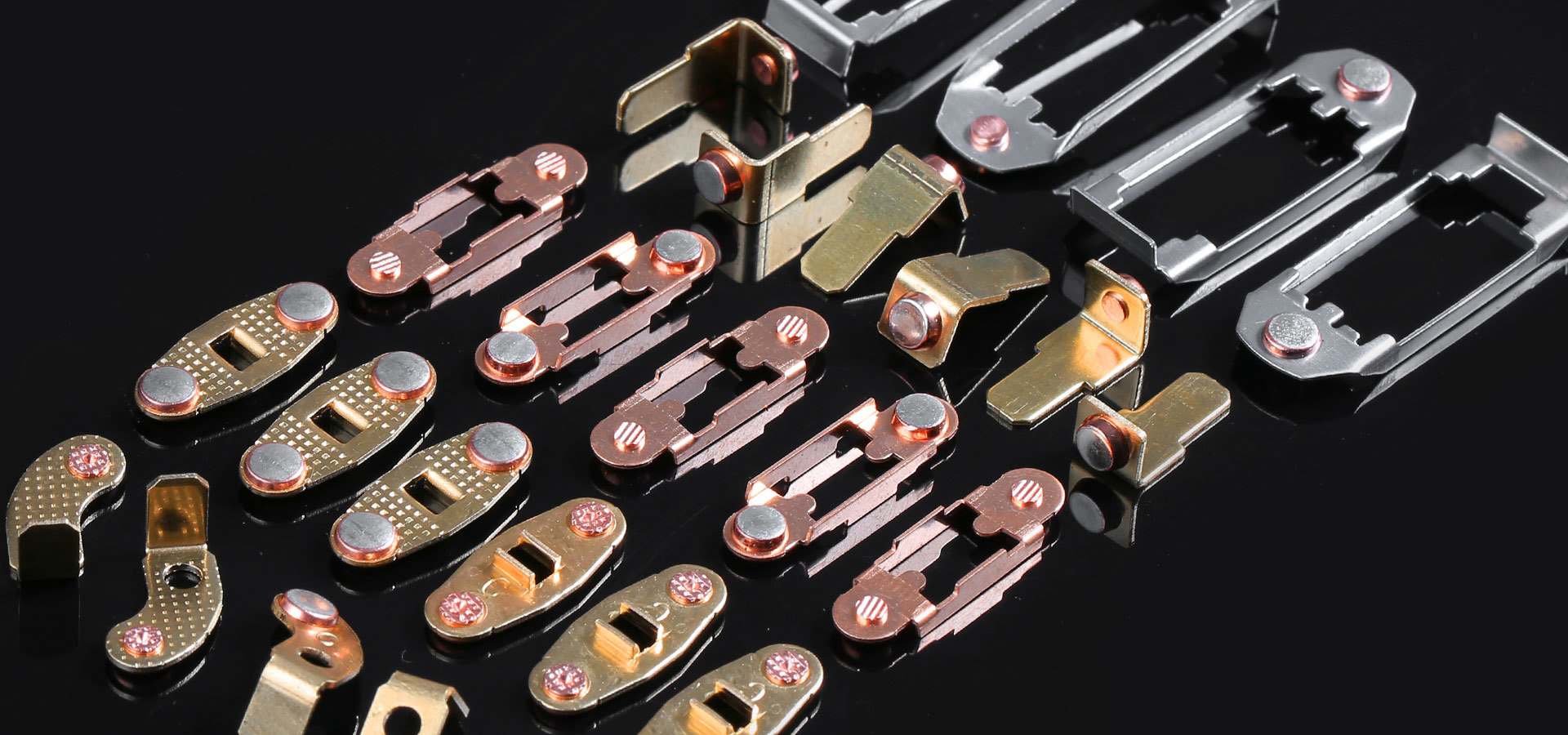

Advantages and uses of powder metallurgy products

Release Time:

Dec 26,2023

Powder metallurgy is the production of metal or metal powder (or a mixture of metal powder and non-metallic powder) as raw materials, by forming and sintering, the manufacture of metal materials, composite and various types of products process technology.

Powder metallurgy is the production of metal or metal powder (or a mixture of metal powder and non-metallic powder) as raw materials, by forming and sintering, the manufacture of metal materials, composite and various types of products process technology.

The advantages of powder metallurgy:

1. Powder metallurgy technology can limit the reduction of alloy composition bias, eliminate coarse, uneven forging organisation.

2. Can easily achieve a variety of types of composite, the full development of the respective characteristics of the component materials, is a low-cost production of high-function metal-based and ceramic composite materials process technology.

3. It can realise the net near-forming and automatic mass production, thus, it can effectively reduce the resource and energy consumption of production.

4. It can make full use of ores, tailings, steel-making sludge, rolling steel scales, and recycled scrap metal as raw materials, which is a new technology that can effectively carry out material regeneration and comprehensive utilisation.

5. It can produce materials and products with special structure and function which cannot be produced by ordinary smelting method.

Powder metallurgy products have a wide range of applications, from general mechanical manufacturing to precision instruments; from hardware tools to large-scale machinery, carbide mechanical forming machine, from the electronics industry to the motor manufacturing, from the civil industry to the military industry, from the general technology to high technology, can be seen in powder metallurgy process.

Keywords:

More information