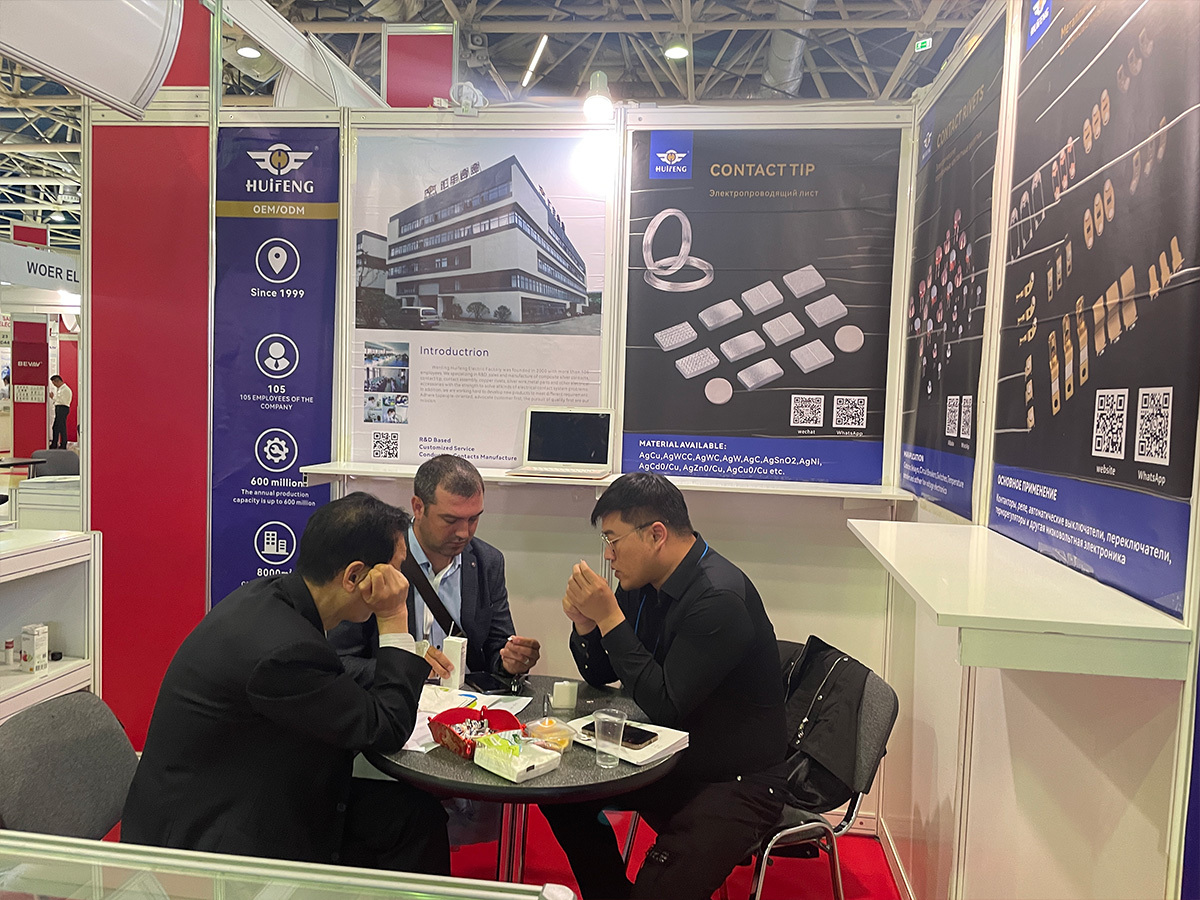

Russian Exhibition Information

It shows our company's electric power, electronics and new energy-related products and application solutions. In this exhibition there are so many customers visit our booth, which increases opportunities for Russia and Turkey cooperation.

Dec 18,2023

Analysing the application and necessity of powder metallurgy

Powder metallurgy can be defined as the process of preparation and processing of powder metallurgy. Iron powder and non-ferrous metals are known as powder metallurgy. Powder metallurgy process: these factors make the process suitable for batch production. It mainly consists of four basic steps. Powder preparation, mixing and blending, compaction and sintering. Sometimes, this process is completed by some auxiliary manoeuvres such as sizing, embossing, osmosis exudation, hot forging, etc.

Dec 26,2023

What do I usually need to look for when choosing hardware tools?

Hardware industry as a traditional manufacturing industry, a long history, and inside the product is also diverse. How can you tell the good and bad of a hardware tool so as not to be deceived it, the next with the editor to understand!

Dec 26,2023

Must See! Overview of Powder Metallurgy Moulding Features and Benefits

We all recognise some of the common metal forming techniques such as forging, casting and sheet metal forming. But have you ever heard of metal powder compaction, powder metallurgy compression moulding, sintering or metal shot forming? Dial cases, bronze coloured bushings and surgical implants are all tied together by a common rope of powdered metal. Yes, all of these components are manufactured using powdered metal as the raw material.

Dec 26,2023

Application areas and advantages of solid rivets are introduced

Solid rivets is a structural rivets, in many different industries are used in a variety of different environments to play a better role in riveting connection, the following small make up for you to introduce this category of rivets commonly used and some of its advantages.

Dec 26,2023

What is the difference between a semi-hollow rivet and a solid rivet?

How about common solid rivets compared to semi-hollow rivets? When it comes to rivets, all of my friends should know that it is a type of metal fixing used to dry join various materials. It is not only varied but also very useful. The common ones are solid rivets and semi-hollow rivets. What is the self-punching of these two types of rivets? Let's see. The elastic deformation of a solid rivet is much drier than its plastic deformation, so only its elastic deformation is emphasised. The plates to be joined are fixed between the concave contact and the crimp ring, the rivets are fitted, the punch shaft moves down, the solid rivet penetrates the top and bottom plates, punching out small pieces of metal, and then some of the bottom plate is pressed into the ring groove by the reaction force of the lower die. This method will produce a bottom groove and interlocking joint.

Dec 26,2023

Advantages and uses of powder metallurgy products

Powder metallurgy is the production of metal or metal powder (or a mixture of metal powder and non-metallic powder) as raw materials, by forming and sintering, the manufacture of metal materials, composite and various types of products process technology.

Dec 26,2023

Hollow rivets can be divided into which categories? What is the difference between them?

The application of rivets in life is very wide, small to the clothes, toys fixed, large to the structure of the tent house, rivets are everywhere in life. Different rivets in different areas have excellent play, so the classification of rivets is very much, universal rivets, semi-hollow rivets, non-standard rivets, full hollow rivets, solid rivets, etc., today I would like to introduce you to the hollow rivets below can also be subdivided into which kinds, what are the characteristics.

Dec 26,2023