Analysing the application and necessity of powder metallurgy

Release Time:

Dec 26,2023

Powder metallurgy can be defined as the process of preparation and processing of powder metallurgy. Iron powder and non-ferrous metals are known as powder metallurgy. Powder metallurgy process: these factors make the process suitable for batch production. It mainly consists of four basic steps. Powder preparation, mixing and blending, compaction and sintering. Sometimes, this process is completed by some auxiliary manoeuvres such as sizing, embossing, osmosis exudation, hot forging, etc.

Powder metallurgy can be defined as the process of preparation and processing of powder metallurgy. Iron powder and non-ferrous metals are known as powder metallurgy. Powder metallurgy process: these factors make the process suitable for batch production. It mainly consists of four basic steps. Powder preparation, mixing and blending, compaction and sintering. Sometimes, this process is completed by some auxiliary manoeuvres such as sizing, embossing, osmosis exudation, hot forging, etc.

1.Powder metallurgy applications:

1. To produce porous products

2. Bearing of pasteurised alloy for automobile

3. To produce automobile oil pump gears.

4. For the production of cutting tools, wire drawing dies and deep drawing dies.

5. Production of refractory metal composites such as tungsten, molybdenum and tantalum. Used in the manufacture of tungsten filaments and filaments for the lamp industry.

6. Diamond impregnated tools made from a mixture of iron powder and diamond powder.

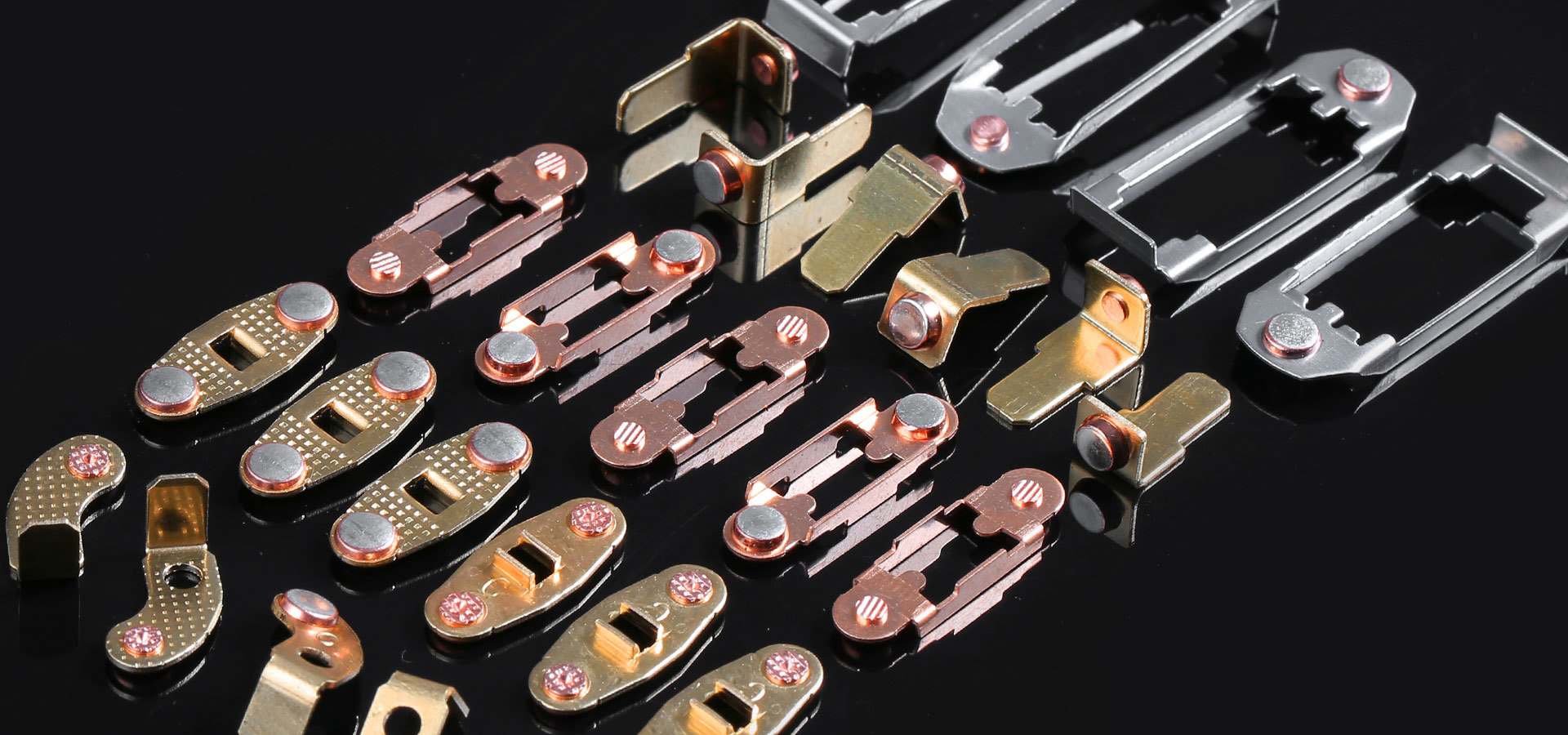

7. Produces electrical contract materials, e.g. circuit breakers, relays and resistance welding electrodes.

8. Automobiles, aircraft, gas turbines, electronic clocks and other parts.

9. Vacuum cleaner parts, refrigerator parts, spray gun parts, sewing machine parts.

2. The necessity of powder metallurgy:

Powder metallurgy becomes very important in the following cases:

1. The melting temperature of the two elements is different.

2. Melting and curing leads to poor quality.

3. melting will result in unrecognisable composition.

4. Some metals will not form liquid solutions.

Third, the characteristics of powder metallurgy:

1. Powder metallurgy should be heat resistant.

2. The size of the powder particles should enable the powder to pass through the sieve with the grid size.

3. The powder should have good plasticity.

4. It should be able to be cold pressed.

5. The powder should have a good parking factor.

6. It should have good mobility.

7. The powder should be free of oxides and the surface should be clean.

8. The ratio of compacted density to apparent density of the powder should vary between 2:1 and 3:1.

Keywords:

More information